Characterization of Mayonnaise with DWS Microrheology

Related Product

DWS RheoLab™

The DWS RheoLab™ is a contact-free rheometer. It provides access to the sample's viscoelastic properties over an unmatched frequency range and enables the study of textures and microstructures while requiring only small sample volumes.

Summary

In this application note, we show how to use the DWS RheoLab from LS Instruments to facilitate the formulation and quality control of a low-fat mayonnaise.

Diffusing Wave Spectroscopy (DWS) is a powerful optical characterization method, especially well suited to study the rheological properties of turbid, white samples such as cosmetic and pharmaceutical creams or dairy products. The method is based on the analysis of the fluctuations of coherent laser light scattered multiple times within a sample [1]. The DWS RheoLab is a versatile tool to conduct such measurements.

The purpose of this application note is to demonstrate that DWS is an ideal tool to study complex emulsions, which are frequently encountered in the food industry. We illustrate this on mayonnaise, a product where the rheological properties are not only important for the production process but also crucial for the commercial success as they are linked to their sensory properties [2,3].

Mayonnaise is an oil-in-water emulsions, containing about 80% oil in traditional recipes. The oil content of mayonnaise substantially affects the rheological properties. In full-fat mayonnaise, the compact packing and the compression of the oil droplets determine the rheological behavior. On the other hand, low-fat mayonnaise typically contains 30% oil only, which is well below the limit of closest packing of uniformly sized droplets (approximately at 64%). As a consequence, the rheological behavior of low-fat mayonnaise is mainly determined by their continuous phase. Typically, the oil in low-fat mayonnaise is partly replaced by water and an appropriate thickener is added to modify the rheological properties of the continuous phase in the emulsion. Suitable thickeners are xanthan gum, starches, or other hydrocolloids that form a gel-like structure in the continuous phase. The concentration of these thickeners is typically on the order of 0.5 wt% but might depend on supplier and lot. In this application note, we employ the DWS RheoLab to facilitate the formulation of a low-fat mayonnaise.

Sample preparation

We prepare different batches of model low-fat mayonnaise that we characterize by performing DWS microrheology measurements. The model mayonnaises are prepared by gradually adding sunflower oil (35 wt% final concentration) to a mixture of egg yolk (10 wt%), mustard (1 wt%), water and xanthan gum, while vigorously stirring with a hand beater. We prepare samples with xanthan concentration of 0.3 wt%, 0.4 wt%, 0.5 wt%, 0.6 wt%, and 0.9 wt%.

The transport mean free path l* of the model mayonnaise is about 340 µm. It is easily determined by the DWS RheoLab. In addition, we include a commercial low-fat mayonnaise from a local supermarket (Thomy light, Nestlé) in our study. The commercial product contains roughly 35 wt% sunflower oil. The value of l* of the commercial product is found to be 152 µm. All DWS measurements are carried out in transmission mode using cuvettes with a thickness of 5 mm. The total measurement time is set to 180 s.

Results and discussion

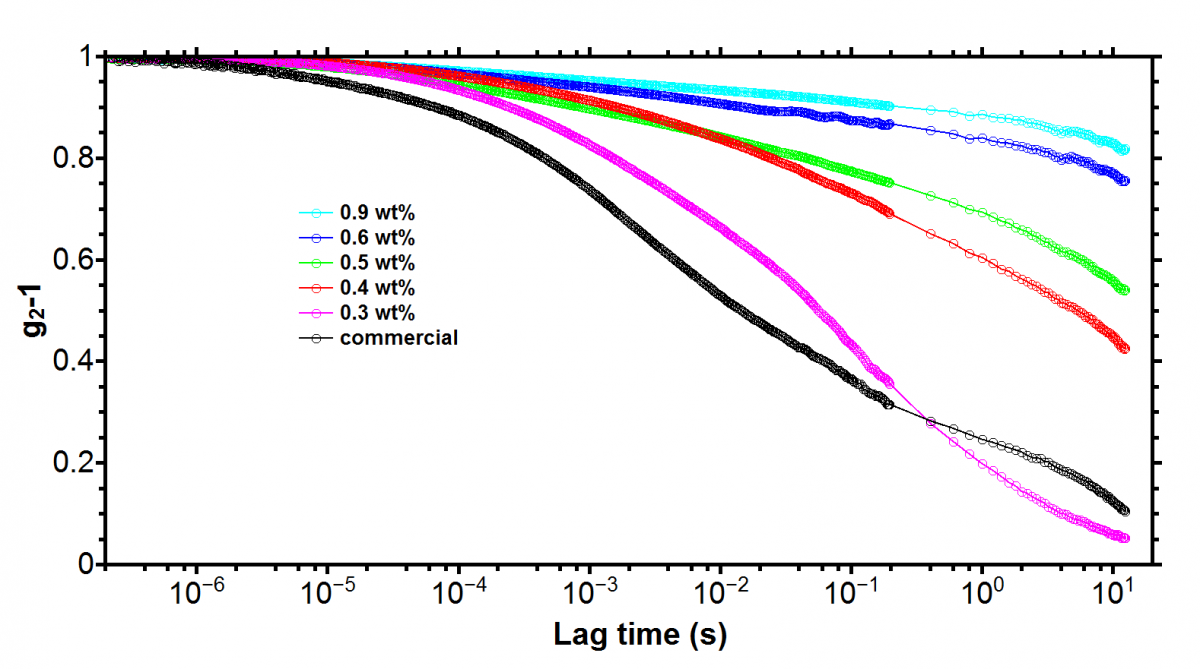

Figure 1 shows the normalized intensity correlation functions ICF's (g2-1) of the prepared model low-fat mayonnaise. The influence of the added xanthan gum is clearly visible. Increasing the xanthan concentration shifts the decay of the ICF towards larger lag times. In DWS, such a shift of the decay of the ICF towards larger lag times is linked to the slowing down of the dynamics of the scattering objects. In our case, the scattering objects are oil droplets that undergo Brownian motion in the continuous phase. The observed slower dynamics can, therefore, be associated directly with an increased viscosity of the continuous phase. In other words, the DWS raw data confirms the role of the added xanthan as a thickener that slows down the Brownian motion of the oil droplets and the decay time is a measure of the viscous relaxation of the product.

We find that the commercial mayonnaise shows a faster decay compared to the model formulations. However, the direct comparison of the ICF to those from the model mayonnaises is not possible because the decay time depends significantly on l*, which is considerably smaller for the commercial product compared to the model mayonnaises. The latter might be due to a different size distribution of the oil droplets.

Figure 1. Intensity correlation functions (ICF's) of different batches of model mayonnaise where the xanthan gum content was varied. The data of a commercial low-fat mayonnaise is shown for comparison.

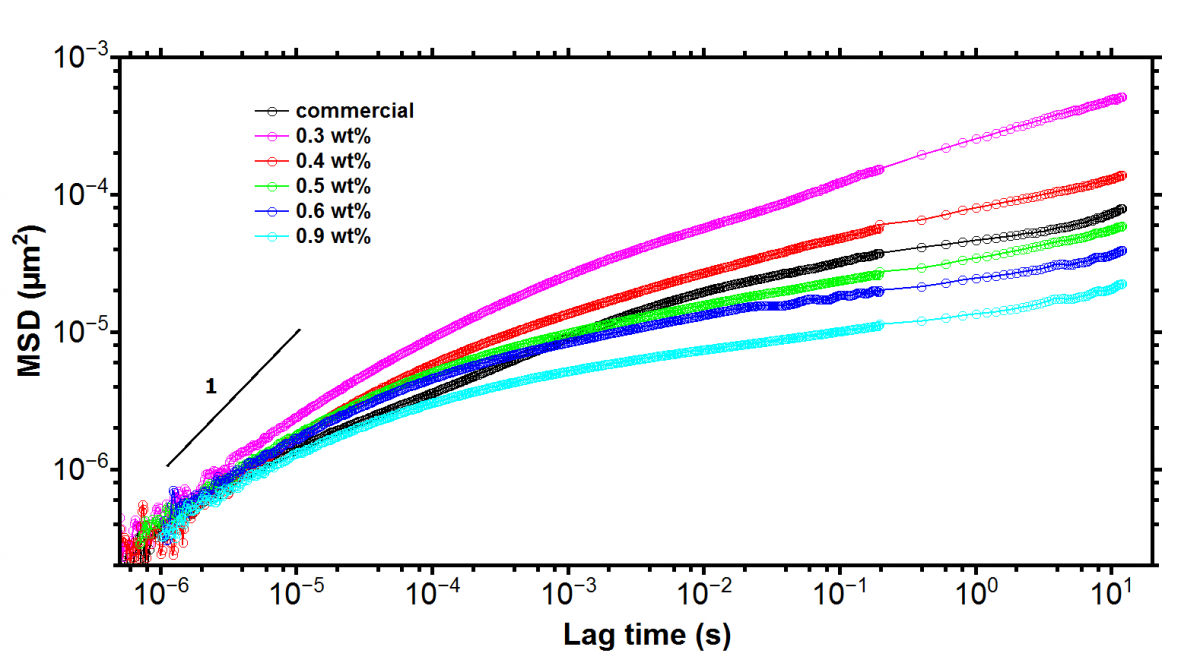

In order to allow a direct comparison, it is more convenient to compare the mean square displacements (MSD's) because the MSD does not depend on l*. The MSD is a measure of the mobility of the oil droplets in the emulsion. The DWS RheoLabsoftware directly calculates the MSD's from the measured ICF's and the results are shown in figure 2. At very small lag times, all data show approximately diffusive behavior, i.e. MSD with a slope equal to unity. At larger lag times the MSD data show sub-diffusive behavior with a slope that decreases with increasing xanthan concentration. The MSD data confirm the observation that the mobility of the oil droplets decreases with increasing xanthan concentration. The MSD of the commercial mayonnaise resembles closest the one of the model mayonnaise with 0.5 wt% xanthan.

Figure 2. Mean square displacements (MSD) of the model mayonnaise with different xanthan content compared to the commercial product. The line indicates a slope equal of unity.

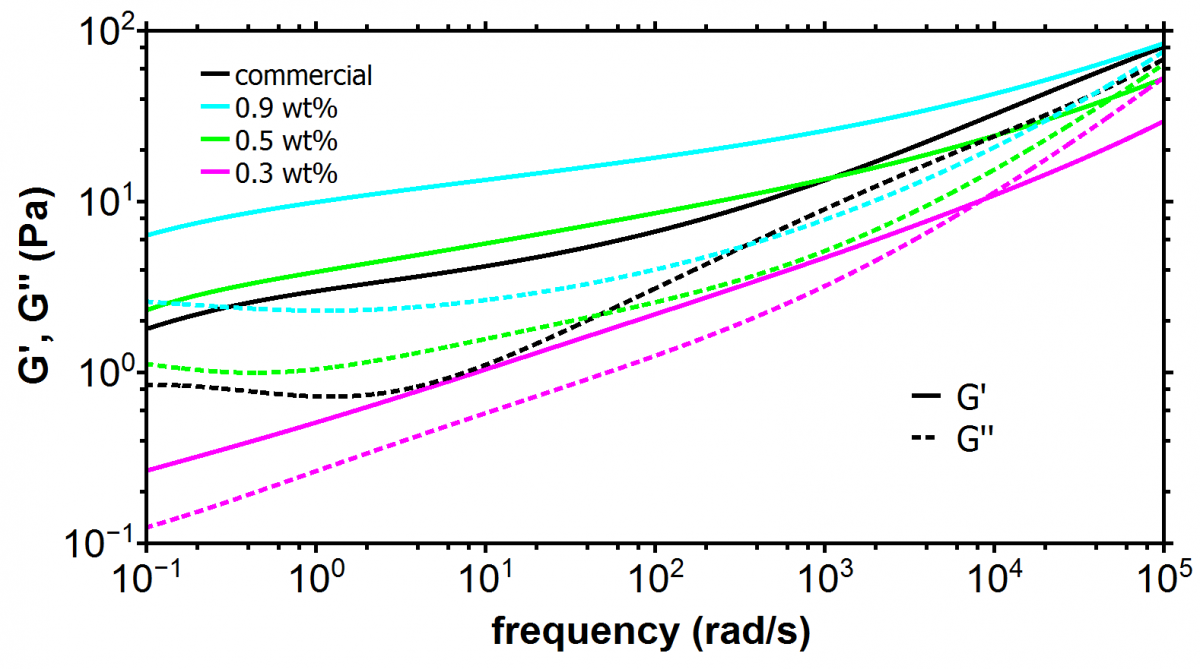

From the MSD data, the software of the DWS RheoLabcalculates the frequency dependent elastic modulus G'(ω) and the loss modulus G''(ω). As normalization parameter, the average size of the oil droplets is required and is directly entered in the corresponding field in the RheoLab software. To predict the rheological properties we assume a mean value of 10 µm based on the optical microscope studies by Hou-PinSu et al. [4]. Figure 3 shows the resulting data for the model mayonnaise (only three xanthan concentrations are shown for better readability) and the commercial low-fat mayonnaise. All data sets show a solid behavior (i.e. G'>G'') over the accessed frequency range, except at very high frequencies (>104 rad/s). With increasing xanthan content, the curves shift towards higher moduli. This observation, combined with the shape of G' and G'', is in line with the assumption that the xanthan in the continuous phase of the emulsion forms a weak gel where the gel strength increases with the xanthan concentration [5]. The mesh size of the xanthan gel is on the order of 40 nm for a xanthan concentration of 0.5 wt% [5], and is thus much smaller than the oil droplets.

At low xanthan concentration, the gel has low stiffness (see Figure 3) and the oil droplets are relatively free to diffuse which leads to an MSD with pronounced positive slope towards large lag times (see Figure 2). In contrast, at high xanthan concentrations, the gel has sufficient stiffness to trap the oil droplets, which reduces the MSD values at larger times significantly.

Figure 3. Storage moduli (full lines) and loss moduli (dashed lines) of the model mayonnaise with different xanthan content compared to the commercial product.

Conclusion

We applied DWS microrheology to a series of model low-fat mayonnaise with different contents of thickener (xanthan) and to a commercial low-fat mayonnaise. We could show that this novel characterization technique allows quantitative measurements of the effect of the thickener in the formulation and enables us to carry out a comparison with a commercial product.

This study demonstrates the advantages of DWS microrheology to support the formulation process of emulsions stabilized by hydrocolloids during the development and for quality control. All measurements were conducted with the DWS RheoLab.

Acknowledgements

This work was supported by Marie Curie Initial Training Network: SOMATAI (“Soft Matter at Aqueous Interfaces”).

References

[1] D.A. Weitz, and D.J. Pine, Diffusing-Wave Spectroscopy. In Dynamic Light Scattering; Brown, W., Ed.; Oxford University Press: New York, 652-720 (1993).

[2] Petr Stern, Helena Valentová, Jan Pokorny, Rheological properties and sensory texture of mayonnaise, J. Lipid Sci. Technol., 103 (2001).

[3] Wendin, K. Aaby, K. Edris, A. Ellekjaer, M. P. Bergenstahl, B. Johansson, L. Willers, E. P. Solheim, Low-fat mayonnaise: influences of fat content, aroma compounds and thickeners. Food Hydrocolloids, 11 (1997).

[4] Hou-PinSu, Chuang-Ping Lien, Tan-Ang Lee and Ruo-Syuan Ho, Development of low-fat mayonnaise containing polysaccharide gums as functional ingredients, J Sci Food Agric, 90 (2010),

[5] K.v Gruijthuijsen, H. Vishweshwara, R. Tuinier, P. Schurtenberger, and A. Stradner, Origin of suppressed demixing in casein/xanthan-mixtures, Soft Matter, 8 (2011).