Gel Point Determination

Contact-free & non-destructive rheology

The development of new and innovative products in the pharmaceutical, food and personal care industries requires significant research, relying on advanced methodologies. Capturing the time and precise conditions at which a novel formulation gels, and its resulting rheological characteristics, can make the difference by speeding up your product discovery efforts.

LSI is a pioneer in the field of contact-free rheology using Diffusive Wave Spectroscopy and with the DWS RheoLabTM offers the most precise tool to characterize your new product formulations in native conditions.

Featured Product

With the DWS RheoLabTM, LS Instruments offers the world's only optical rheometer based on DWS technology.

- Easy measurement setup

- Non-Invasive Measurements

- High Sensitivity to Microstructure Changes

- Wide Range of Measurable Concentrations and Conditions

- Real-Time Monitoring of Gelation Process

- High-frequency

Features

Contact-free

Fast

Sealed-sample

Small volumes

As little as 4μL of sample requiredContact-free rheology

Contact-free rheology (also known as microrheology) is a method in which the trajectory of particles in a medium is measured.

With diffusing wave spectroscopy (DWS), LS Instruments offers a unique technology that determines the rheological properties of the medium by measuring changing light patterns behind the sample caused by the Brownian motion of particles in the sample.

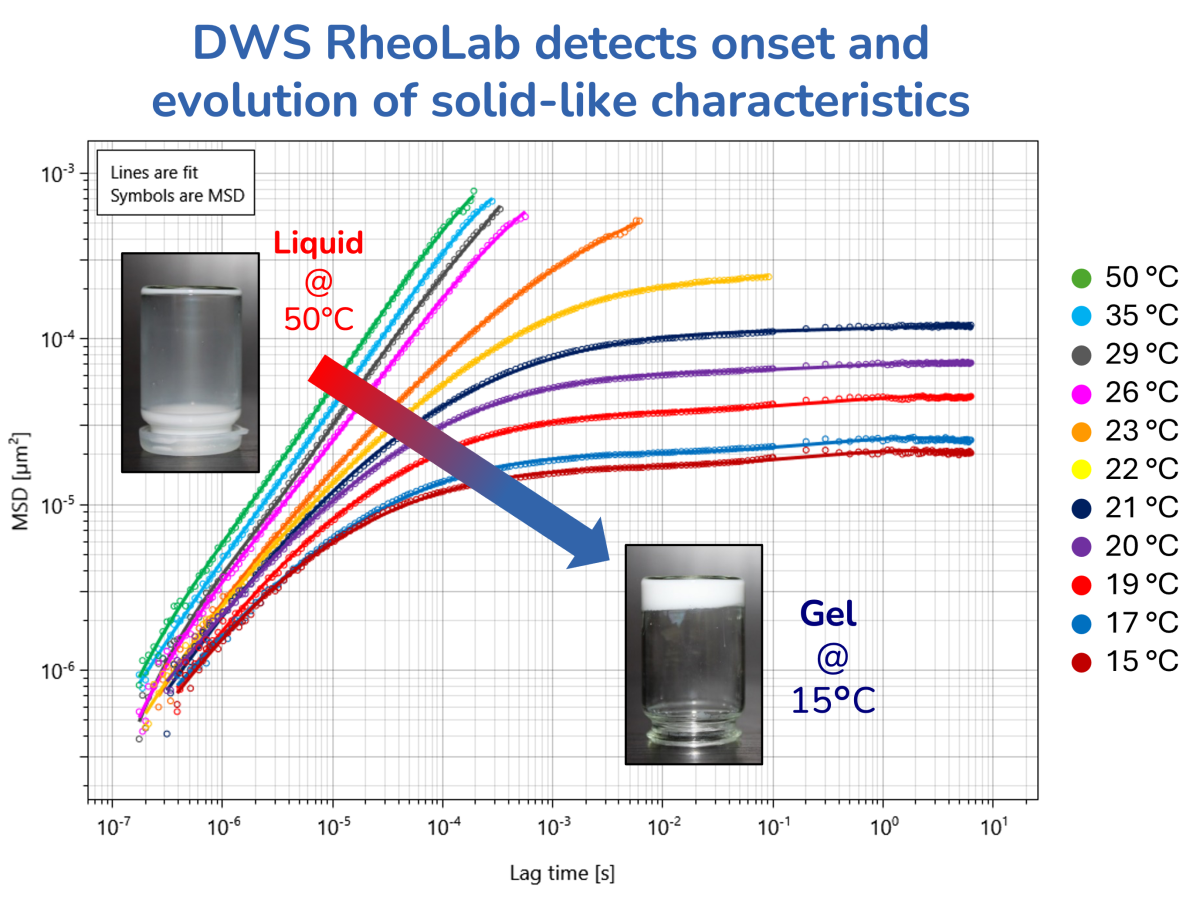

In simple terms, particles move more or less freely in the medium depending on the network formed. On this basis, DWS can be used to calculate the mean squared displacement (MSD) as well as storage and loss moduli and viscosity of viscoelastic samples.

Particle Motion in the Sample

Newtonian Liquid

Particles moving freely

Viscoelastic Material

Particles entrapped by network

Benefits of diffusing wave spectroscopy (DWS)

Bulk rheology has emerged as a primary method for assessing the rheological characteristics of samples. However, when observing gelation mechanisms involving the formation of structures by chemical cross-linking or physical network association, it is essential to minimize the external forces acting on the sample to avoid disturbances in structure development.

Additional complexity arises when preformed gels are examined. For example, careful preparation techniques such as the use of templates or precise cutting are required to ensure optimal adhesion to the intended geometry. Subsequently, fine-tuning the application of force, taking into account the surface topography and thickness of the gel, is crucial.

DWS presents a solution to address these challenges:

|

✅ the non-invasive optical measuring principle ensures that samples remain undisturbed, allowing for uninterrupted growth of structures. This facilitates precise observation of processes such as network formation. ✅ the system enables samples to be conveniently prepared directly within the measuring cuvette, offering the flexibility of reusing them for stability studies. |

With its non-destructive approach, DWS provides an ideal basis for measuring sensitive samples. DWS also offers other interesting advantages:

|

✅ The cuvette-based technology makes it easy to insert new samples and thus increase the measurement throughput. ✅ Sample volumes as small as 150 µL can be measured. ✅ The DWS measuring principle measures a full frequency spectrum in a single measurement, which further increases throughput. |

With DWS, you not only gain precise insights into your samples but also optimize the efficiency of your experimental workflows.

Figure above: Extract from a gelatine sample characterization at different temperatures. The mean squared displacement (MSD) is an indicator of the degree of freedom of the particles in the system. A straight line indicates full freedom of movement of the particles and therefore a completely viscous system. The more the curve flattens out, the greater the restrictions on the freedom of movement of the particles - a sign of forming networks.

Hydrogel Characterization: A Comparative Study of DWS and Bulk Rheometry

Read in this application how DWS is used to characterize hydrogels.

The measurements were performed on our DWS instrument, the DWS RheoLabTM.

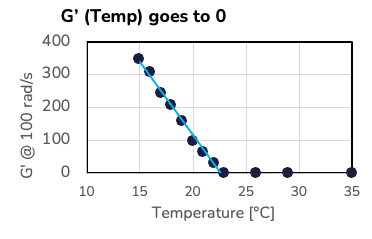

Determining the Gel Point as a Function of Temperature

Read in this application how DWS is used to measure the gel point temperature.

The measurements were performed on our DWS instrument, the DWS RheoLabTM.