Rheometers

Rheometers are used to measure the rheological properties of materials. Typically they relate a dynamic quantity (a force, a torque, or a pressure) to a cinematic one (a displacement, a rate, etc). Based on the geometrical parameters of the instrument, which are known, the physical properties of the material are determined.

The most common rheometers are the rotational rheometers. These measure the macrorheological properties of a sample. In a rotational rheometer, a continuous shear motion is applied to a material by the relative rotative motion of two surfaces [1].

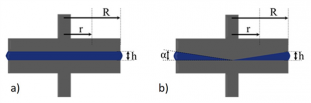

Several geometries of the surfaces are available to optimize the measurements according to the different properties of the fluid to be studied. The most simple and common is the parallel plate geometry (Figure 1a).

While this geometry allows an easy loading of the sample and the possibility to vary the sample thickness h, the shear rate

applied depends on the radius r. This means that only the viscosity of Newtonian systems can be measured, whereas, for non-Newtonian ones, only estimates can be obtained. Eqs. (1) shows the parallel plate geometry.

(1)

where is the angular speed and M is the torque.

A constant shear rate is obtained by the cone-plate geometry (Figure 1b). In this case, when the angle of the cone , is small, then

can be expressed as:

(2)

Figure 1. (a) Parallel plates and (b) cone-plate geometry.

Pros & Cons

The parallel plate and the cone-plate geometries are only two of a wide range of possible configurations employed in rotational rheometers. However, despite the numerous alternative geometries and the possibility to investigate the dynamics of fluids through numerous different typologies of measurements, they each have their specific limitations. These are due to both the intrinsic properties of the materials under investigation as well as the technological restrictions of rotational rheometers.

Some of the most important limitations are:

- Exposure to air: All geometries are air-open. This can be dangerous for all such systems whose fumes are toxic or damage the reliability of the measurement; moreover, this renders it impossible to recover those precious samples, which, once exposed to the air, are irreversibly contaminated.

- Sample volume: relatively high amounts of sample volume are required, which, sometimes are not available or are very expensive.

- Deformation history: Some materials present an intrinsic storage deformation, which will affect the measurement results and, thus, the measured properties. A shear motion, the so-called pre-shear, is applied to the material before the real measurement is run. It this way a fixed deformation is induced into the fluid and all the measurements will be characterized by the same deformation history. Anyway, this is an invasive procedure, which aims to change the starting state of the system.

- Torque values: All rotational rheometers have technological upper limits, which allow investigating the oscillatory and shear dynamics of a material only at low and intermediate frequency and shear rate values. However, many parameters crucial to the understanding of the sample, development and process of a material, are shown in the high frequency region.

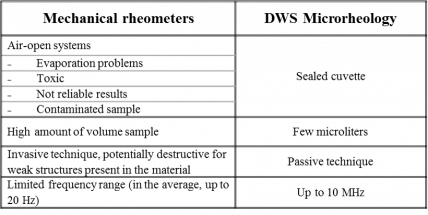

Microrheology comes to the rescue of rheometers, thanks to its sealed cuvettes, passive approach, and principle that allow reaching very high frequencies, otherwise inaccessible. This non-invasive technology, however, must be considered only complementary to classical mechanical rheometers.

Table 1 compares the most important limitations of mechanical rheometers compared to an instrument based on DWS Microrheology.

Table 1. Limitations of mechanical rheometers that can be overcome by DWS Microrheology

[1] K. Walters, Rheometry, Chapman and Hall, London 1975.